【CHINAPLAS】Fancier Surface and Lower Cost Thanks to RIM 2.0

Abstract:

【CHINAPLAS】Fancier Surface and Lower Cost Thanks to RIM 2.0

YIZUMI will present ReactPro Integrated Solution of Polyurethane and Injection Molding (short for RIM) at CHINAPLAS 2021 after the CHINAPLAS 2019 and Germany K show 2019. The 2.0 version of the solution produces parts that are not only soft-touching, self-repair, corrosion-resistant, and scratch-resistant but also with high-gloss, matte appearance. The total cost will be reduced significantly when adopting domestic PU materials.

Jointly developed by YIZUMI and FRIMO Germany, ReactPro Solution satisfies the one-step injection molding requirement, producing plastic parts with polyurethane coating in the same injection molding machine.

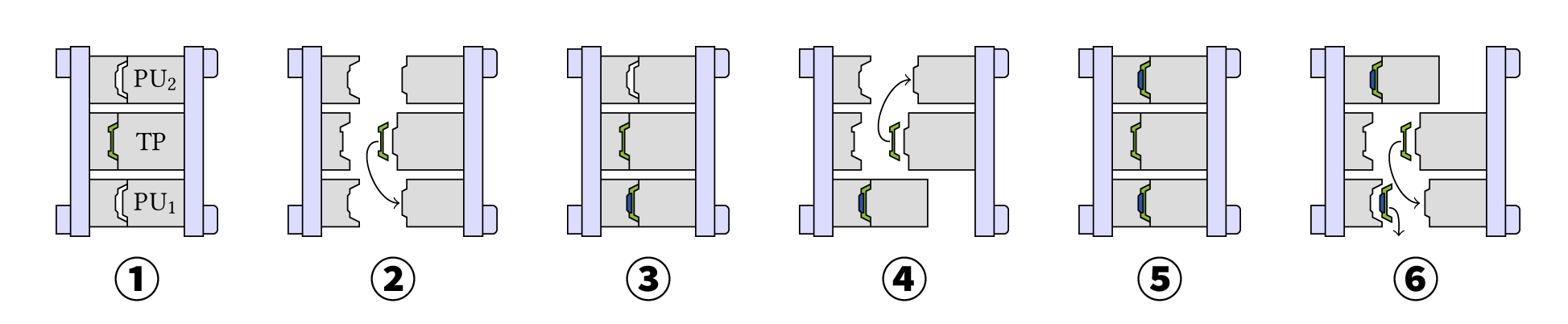

The ReactPro solution adopts the InPUR "1+2" mold technology jointly developed with GK Concept Germany. By means of InPUR "1+2" innovative mold technology, alternate coordination between two PU molds and one injection mold can further reduce cycle time. Although the polyurethane reaction time still takes about 2 minutes, the molding cycle is greatly shortened to about 1 minute. The InPUR “1+2” mold technology doesn’t require any swivel units such as conventional horizontal or vertical rotary tables and therefore the design is more compact, considerably saving the cycle time of batch production.

The engine cover with the soft and self-repairing PU surface below is produced by the ReactPro solution. Its surface transparency and color are adjustable according to the customer's needs, and the 3D depth surface effect is also available. Additionally, the PU material can show both high gloss and matte on the same surface. The PU thickness of the engine cover reaches about 0.5-0.6 mm. And we adopt self-releasing PU material, providing convenience for the entire production process.

YIZUMI’s ReactPro solution is suitable for the production of new-generation automotive upholstery (such as instrument board, door panel, and intelligent component). Some automotive upholstery from BMW and Benz has used polyurethane coating on its decorative surfaces and functional surfaces. Meanwhile, the polyurethane coating has tremendous potential in the 3C and appliance industries due to its good performance, bringing more possibilities for better product design.

YIZUMI can’t wait to meet you at CHINAPLAS 2021. Welcome to our booth! Exhibition Center: Shenzhen World Exhibition & Convention Center, 12J41

April 13th -16th, Block your date!